Conformal coating is a protective layer applied to electronic assemblies to safeguard them from environmental factors such as moisture, dust, chemicals, and thermal shock. This protective barrier enhances the reliability and longevity of electronic devices, making it a crucial component in various industries.

Why is Conformal Coating Important?

-

Moisture Protection:

- Corrosion Prevention: Moisture can lead to corrosion, which can degrade the electrical conductivity of components and eventually cause failures. Conformal coatings act as a moisture barrier, preventing water from reaching sensitive components.

- Electrochemical Migration: Moisture can facilitate electrochemical migration, a process where metal ions migrate through the circuit board, causing shorts and other electrical issues. Conformal coatings inhibit this process.

-

Thermal Shock Protection:

- Temperature Fluctuations: Electronic devices are often exposed to rapid temperature changes, which can cause thermal stress and fatigue. Conformal coatings provide a thermal barrier, mitigating the impact of temperature fluctuations.

-

Chemical Resistance:

- Chemical Exposure: Electronic assemblies may encounter various chemicals, such as cleaning solvents or corrosive gases. Conformal coatings offer protection against these chemicals, preventing damage to the components.

-

Dust and Debris Protection:

- Contamination Prevention: Dust and debris can accumulate on electronic components, leading to electrical shorts and performance degradation. Conformal coatings create a barrier that prevents the accumulation of contaminants.

-

Vibration and Shock Protection:

- Mechanical Stress: Vibration and shock can cause physical damage to electronic components, leading to malfunctions. Conformal coatings can help absorb some of the mechanical stress, reducing the risk of damage.

Types of Conformal Coatings:

- Acrylic Conformal Coatings: These coatings offer good moisture and chemical resistance but may not be suitable for high-temperature applications.

- Silicone Conformal Coatings: Silicone coatings provide excellent thermal stability and moisture resistance, making them ideal for a wide range of applications.

- Urethane Conformal Coatings: Urethane coatings offer excellent mechanical and chemical resistance, as well as good thermal stability.

- Parylene Conformal Coatings: Parylene coatings are highly pinhole-free and offer excellent dielectric properties, making them suitable for high-reliability applications.

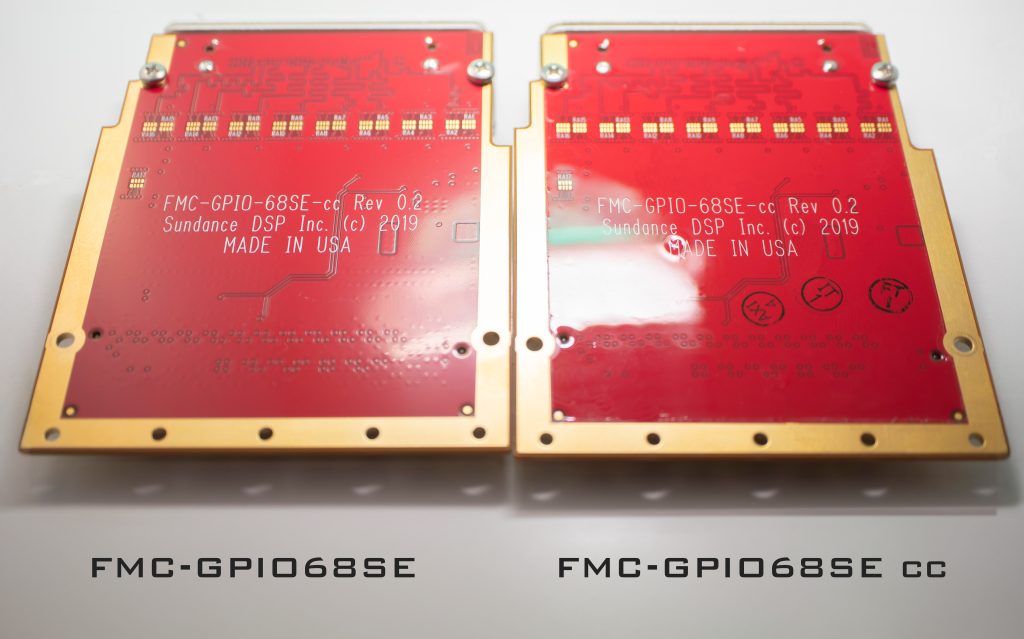

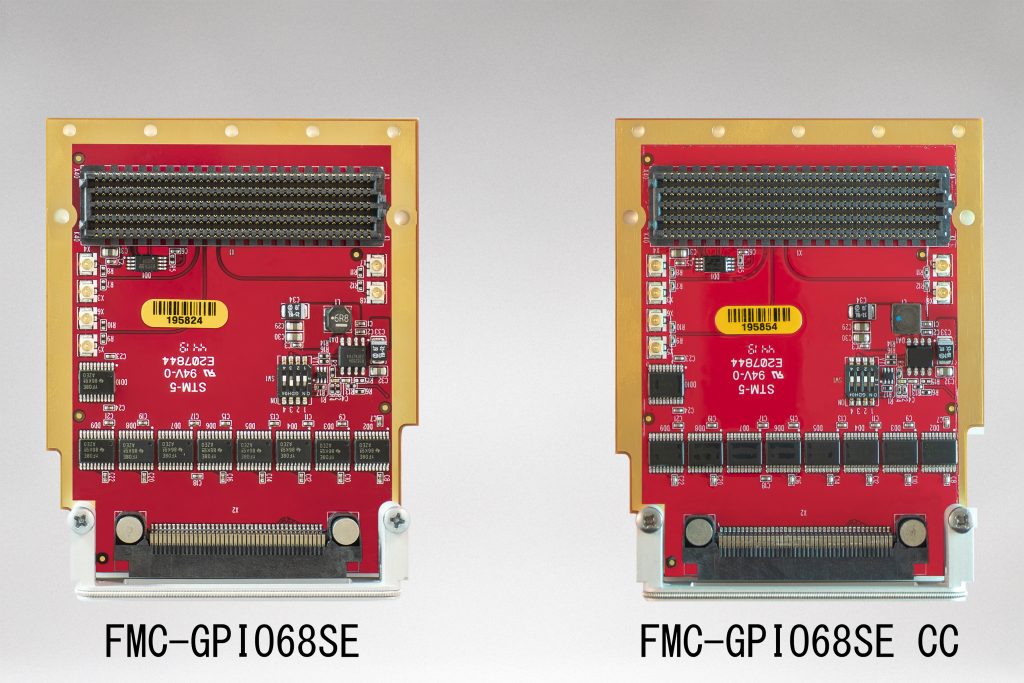

The above images show FMC-GPIO68SE with conformal coating and without conformal coating.